In today’s industrial world, safety and efficiency are paramount, especially in environments where hazardous materials, extreme temperatures, or explosive gases are present. To address these concerns, specialized equipment such as explosion-proof electric butterfly valves is crucial. These valves play a critical role in maintaining both safety and performance, especially in industries like oil and gas, chemical processing, mining, and pharmaceuticals. For many companies, choosing a reliable Explosion-proof Electric Butterfly Valve ODM Manufacturer is essential to ensure that the equipment meets specific needs, is durable, and adheres to industry standards.

Understanding Explosion-proof Electric Butterfly Valves

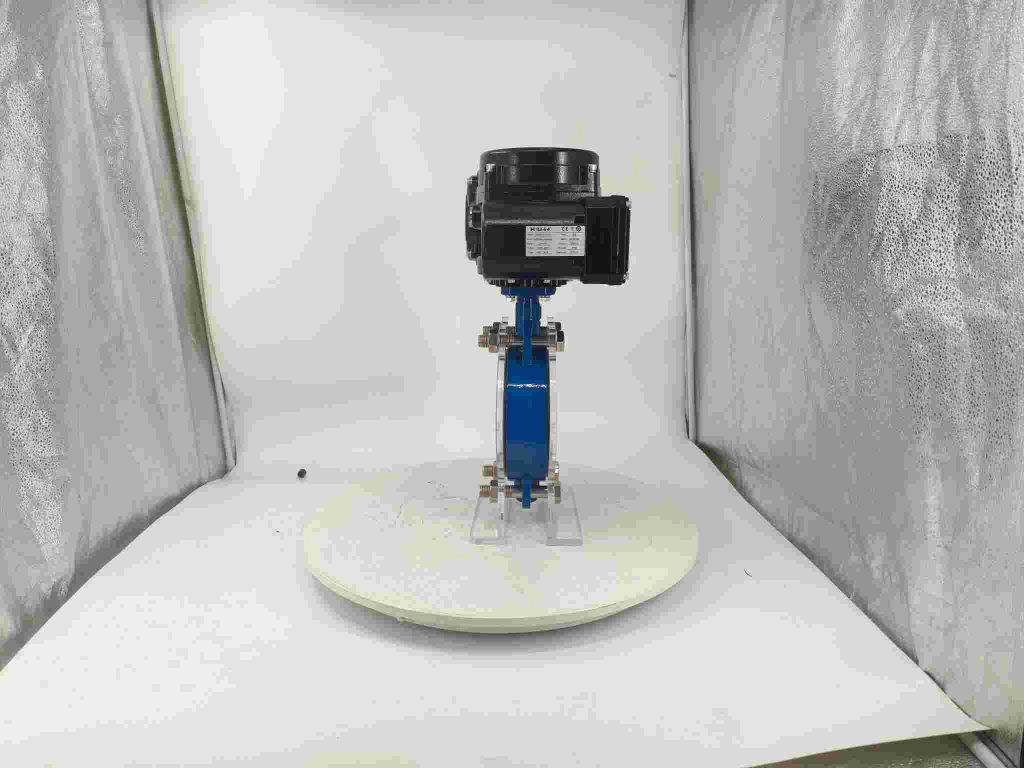

An explosion-proof electric butterfly valve is a type of control valve that uses an electric actuator to regulate the flow of liquids or gases through a pipe or duct. The key feature of these valves is their explosion-proof design, which means they are built to operate safely in environments with a risk of explosion. This is typically achieved through robust construction and the use of materials that prevent ignition or minimize the risk of sparks that could trigger an explosion. These valves are particularly important in industries dealing with volatile substances like natural gas, chemicals, and oil. The electric actuator allows for precise control of flow, making them highly efficient in automation systems. The butterfly valve itself consists of a disc that rotates within the pipe, offering a smooth, controlled flow while minimizing resistance.

Leave a Reply